Tutorial - Evaluation

Project 2

Materials and Tools :

- An object's 3D model (obtained from a colleague)

- 123D Make

- Adobe Illustrator

- 3mm 30x60cm bamboo plywood

- 1 round 1mm metal sheet

- Laser Cutter, at least can take a sheet of 30x60cm

- Sand Bag

- Nylon Bossing Mallet - Round End

- Nylon Bossing Mallet - Flat End

- Polishing Hammer - Flat End

- Mushroom Dollies, bigger and smaller one, depending on pref

Optional Tools (only if you didnt manage to get an item from a colleague):

- An object

- 123D Catch app

- 123D Catch app

- 123D Make

- Spray Paints

• Since this is the second project, I have got the idea of what's the right technique to achieve the model

First thing first, get a 3D model from a colleague. If you dont have any colleague, you have to follow the instructions on Project 1 to produce a 3D model of an object that you choose.

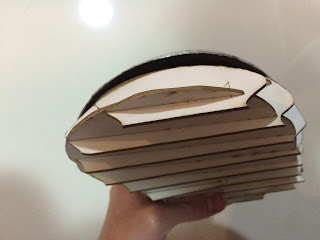

For this project, I choose to make a sectioning model instead of waffling model because waffling model is harder to work with; sectioning model is sturdier, easier to work with, and it is a solid.

So the first step is to make a cutting layout on adobe illustrator. To get the layout, you will need to import your 3D model into 123 Make and make sure that your file is in .STL type. After it's imported to the environment, select the thickness of your material and select SECTIONING on the program. Select the window to preview the sections, then export it into PDF format. Once the PDF is generated, import it into adobe illustrator. The first thing that you might want to do is to tidy up the layout. There are chances that there are small parts that can be inserted into other page. Do this if you feel like saving some space and increace the chance to reduce printing sheets. When the file is in adobe illustrator, make sure that the layout that you want to cut is coloured in RGB red and has a line thickness of 0.001. Once those settings are done, press print and select your laser cutter as your printer. Open the printer program, place your 30x60cm sheet into it, and do some caliberation. Make sure that every thing that you want to be print is in the area where the sheet is placed. Also make sure that the sheet isnt bending. If it's bending, there are chances that it'll not cut through, so you definitely dont want any bend sheets. If the bending isnt bad, just loke a small curve, it still can be used but ofcourse with a risk. If the sheet is bended, you will need to add a couple of pins to keep the sheet in place, depending on how bended it is, more pins might be needed. After all the sheet settings is done, make sure the cover of the printer is closed, dust suction is on, and select the right material and its thickness, in this case it's general medium wood, 2 mill; then press print to start printing. You have to redo the caliberation everytime you want to print to make sure the printer is doing its jobs properly. If the material catches on fire, pause the printer and use the fire extinguisher. Once all sheets have been printed, turn the dust suction and printer off.

After all parts have been extracted from the frames, the assembly of the model starts by sorting the pieces based on the number that is printed on it. Smallest number should be at the bottom. Once the pieces are in correct order, match the sides and start gluing the pieces to make the model. Make sure that you let the glue dry before working with it.

Once the sectioning model is ready, prepare the tools and material to make the metal skin of the model. The first thing that you need to do will be to determine the centre of the metal plate and draw approximately the major radiuses of the model. This way you will know how much you need to work on every part of the radius. Moving on, next thing that need to be done is shrinking. Same way as project one, you will need o shrinking it to a bowl. In this case, since my model has different layers or different radiuses, the amount of shrinking i need to do varies depending on how thigh the skin needs to be on different layer of the radius. Once you have done enough shrinking to make the skin fits the model, start denting the skin to make closer fit by placing the skin on the model and hitting on the dented area. During the fitting process you might neees to do more shrinking to make it fit better.