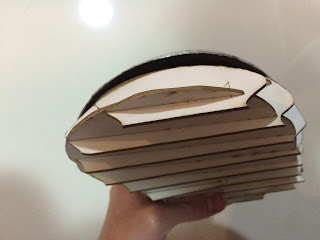

A. Laser Cut

The waffle is made from 2mm cardboard

B. Metal Plate

The metal skin is made from a 1mm round metal sheet. The process was from transforming it into a bowl first, then continues on forming the complex part on the left side where the thumb rest. After that part is formed, continues with curving the right and back side where the palm is resting

C. Combining the skeleton and skin

Generally, I'm pretty pleased with the 2 models, they fits perfectly. If i get the chance to improve them, the first thing that I will do would be reforming the skin so that it is more fluid and fits better to the skeleton. Secondly, trying different methods of forming so that I wont't leave so much scar on the metal sheet. Third, make the waffle with more sections and stronger materials such as timber so that the form is clearer to see and easier to work on the skeleton

No comments:

Post a Comment